This is MASSIVE when you think about how much plastic we use on a day-to-day basis. Every person in Australia creates an average 107 kilograms of plastic waste each year, according to a 2016 report.

All that litter, with nowhere to go?

Thankfully scientists are finding more construction uses for recycled plastic building materials – with promising results.

This is MASSIVE when you think about how much plastic we use on a day-to-day basis. Every person in Australia creates an average 107 kilograms of plastic waste each year, according to a 2016 report.

All that litter, with nowhere to go?

Thankfully scientists are finding more construction uses for recycled plastic building materials – with promising results.

Contents

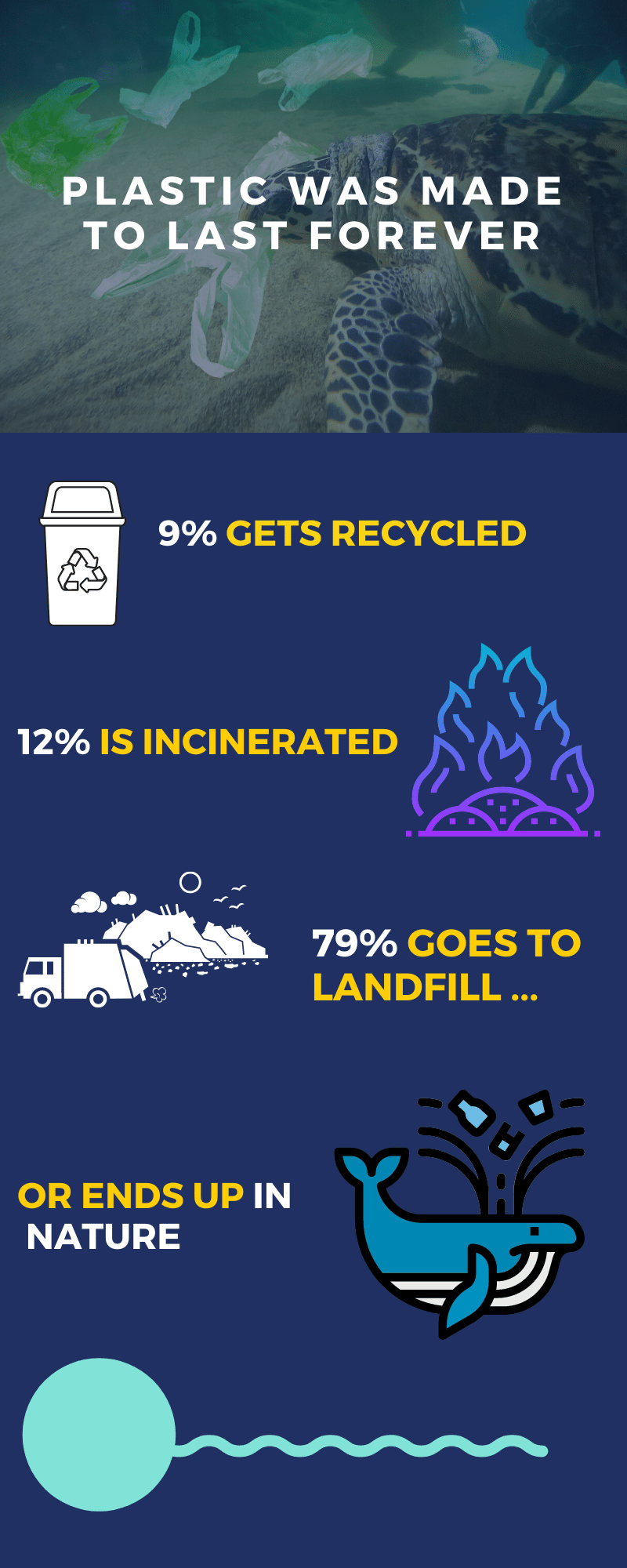

Our oceans are littered with millions of tonnes of plastic waste – which takes 50 to 600 years to break down, depending on the product.

Our oceans are littered with millions of tonnes of plastic waste – which takes 50 to 600 years to break down, depending on the product.

“Without significant action, there may be more plastic than fish in the ocean, by weight, by 2050.” The New Plastics Economy report by the Ellen MacArthur FoundationTragically, wildlife on the land and sea become entangled in plastic, or mistake it for sustenance. Toxic chemicals also leech into water and food supplies – compromising our health. If you believe this problem is too widespread to tackle, you’re not alone. It’s overwhelming. Thankfully the construction industry is adding to solutions popping up in various Australian sectors, as the need for sustainability grows. Good timing too – considering that China banned the import of most plastics in 2018. The rest of the world has little choice but to better manage their own trash now. This begs the question: How is the construction sector rising to the challenge? And what are the disadvantages of using plastic in concrete, bricks and other building materials? (more on this later)

Recycled plastic roads in Australia (cost-effective solution)

If you love the idea of walking on a footpath made out of waste, wait until you drive on a road containing your trash. Sutherland Shire is giving recycled plastic roads a test run, by resurfacing the Old Princess Highway in Engadine. In 2018 builders started laying part of the road with an asphalt mix that contains plastic bags and glass. It’s designed to withstand heavy traffic and handle extreme temperatures, while being cost competitive. But they’re not the first council in Australia to pioneer such a project. Melbourne’s Hume City beat them to it – trialling the new form of asphalt earlier that year, with amazing results. The durable 300-metre stretch of road on Rayfield Avenue uses an affordable and flexible “plastiphalt” mix that resists deformation and fatigue. It contains THOUSANDS of plastic bags, glass bottles and toner from printing cartridges. Consider the environmental impact: This is equal to ten years of rubbish from the yellow bins on that street alone, according to Hume mayor Geoff Porter. “We think that is something to be pretty proud of,” he told the Sydney Morning Herald.Recycled plastic roads started in India…

Plastic roads were first developed in India by Dr Rajagopalan Vasudevan in 2001. He discovered that recycled polymer plastic is an excellent binder, flexible and surprisingly durable. A tar road in the capital Chennai was one of the first to be built using shredded plastic tar. Fast forward to the present and more than 33, 800 kilometres feature the polymer technology. According to the Guardian:“Every kilometer of this kind of road uses the equivalent of 1m plastic bags, saving around one tonne of asphalt and costing roughly 8% less than a conventional road.”The road has withstood floods, monsoons, heat waves and heavy traffic, without deteriorating. It almost seems too good to be true. Some experts say there could be negative consequences in the long-term, such as the breaking down of plastic pieces into the soil and waterways. Read on, we’ll explore this later.

Hospital waste to durable, green concrete (Australia)

Yes, you read that right.

Plastic used in life-saving dialysis could extend the life of concrete, by guarding against corrosion.

Deakin University researchers are blending shredded plastic into their eco-friendly cement mix, in a radical experiment.

So far, so good.

This creates a durable and waterproof concrete, which absorbs 30 per cent less water than alternatives, as seen in initial tests.

Project leader Dr Riyadh Al-Ameri says the finding shows that recycled plastic can help concrete to resist corrosion – which is huge. He’s been nominated as one of Australia’s Most Innovative Engineers in 2018, as a result of his work.

Yes, you read that right.

Plastic used in life-saving dialysis could extend the life of concrete, by guarding against corrosion.

Deakin University researchers are blending shredded plastic into their eco-friendly cement mix, in a radical experiment.

So far, so good.

This creates a durable and waterproof concrete, which absorbs 30 per cent less water than alternatives, as seen in initial tests.

Project leader Dr Riyadh Al-Ameri says the finding shows that recycled plastic can help concrete to resist corrosion – which is huge. He’s been nominated as one of Australia’s Most Innovative Engineers in 2018, as a result of his work.

“If we are able to facilitate production of new types of concrete that will offer better protection, give structures longer life and better performance, as well as help recycle plastic waste, that will be a great achievement.” Dr Riyadh Al-AmeriThere’s no shortage of single-use dialysis products to experiment with, that’s for sure. Dialysis treatments in Australia create 5,100 tonnes of plastic waste every year, according to project collaborator Dr Katherine Barraclough from Royal Melbourne Hospital.

“With increasing numbers of people requiring dialysis in Australia and worldwide, we need to work out ways to reduce the costs of care delivery, as well as play our part in ensuring a healthy environment for future generations.”

People live in “LEGO HOUSES” made from recycled plastic bricks

Colombia is facing two major problems:

The need to accommodate growing numbers of people in its cities.

AND

Plastic pollution – around 650 tonnes is thrown away each day in the capital Bogota alone.

Architect Oscar Mendez is tackling both issues by turning bottles, bags and rubber into durable bricks that build quality houses for people seeking shelter.

“Plastic is a problem everywhere, and people will always need a roof over their head,” he told Forbes.

Two birds with one stone (or brick, you might say)…

His company, Conceptos Plasticos, works with communities across Colombia to build sturdy, fireproof and earthquake resistant homes that require little maintenance.

The recycled plastic bricks are put together like LEGO pieces – and quickly too! A two-story house can go up in five days and there’s no need to put adhesive on the interlocking structures.

To make this possible, the team:

Colombia is facing two major problems:

The need to accommodate growing numbers of people in its cities.

AND

Plastic pollution – around 650 tonnes is thrown away each day in the capital Bogota alone.

Architect Oscar Mendez is tackling both issues by turning bottles, bags and rubber into durable bricks that build quality houses for people seeking shelter.

“Plastic is a problem everywhere, and people will always need a roof over their head,” he told Forbes.

Two birds with one stone (or brick, you might say)…

His company, Conceptos Plasticos, works with communities across Colombia to build sturdy, fireproof and earthquake resistant homes that require little maintenance.

The recycled plastic bricks are put together like LEGO pieces – and quickly too! A two-story house can go up in five days and there’s no need to put adhesive on the interlocking structures.

To make this possible, the team:

Big savings for NZ companies, thanks to recycled plastic blocks

Twenty years. That’s how long it’s taken for New Zealand company Enviroplaz to create a lightweight polymer aggregate that’s made out of plastic waste. It’s called Plazrok. Has all that experimenting been worth it? You bet. The results: Construction companies can save time and money, while building durable structures. This means paying less for transportation and labour, since builders are more productive with lightweight materials.

Construction companies can save time and money, while building durable structures. This means paying less for transportation and labour, since builders are more productive with lightweight materials.

“If you can take, for example, 40 percent of the weight out of a building structure, the engineering loads that change on that and the reduced costs in engineering are enormous.” Pete Hutchinson, Enviroplaz research engineerSustainable construction that generates major savings for business owners? Tick and tick. The best part for green concrete companies: They don’t need to change much to make this reality. A thermal mechanical process turns the waste into aggregate. It doesn’t even need to be cleaned, according to founding director Peter Barrow.

“We don’t take the labels off, we don’t have to disassemble it or take any of the other components off it, we can use it in its entirety,”he told the NZ Herald. The technology has now been fully commercialised and is growing steadily in New Zealand and overseas.

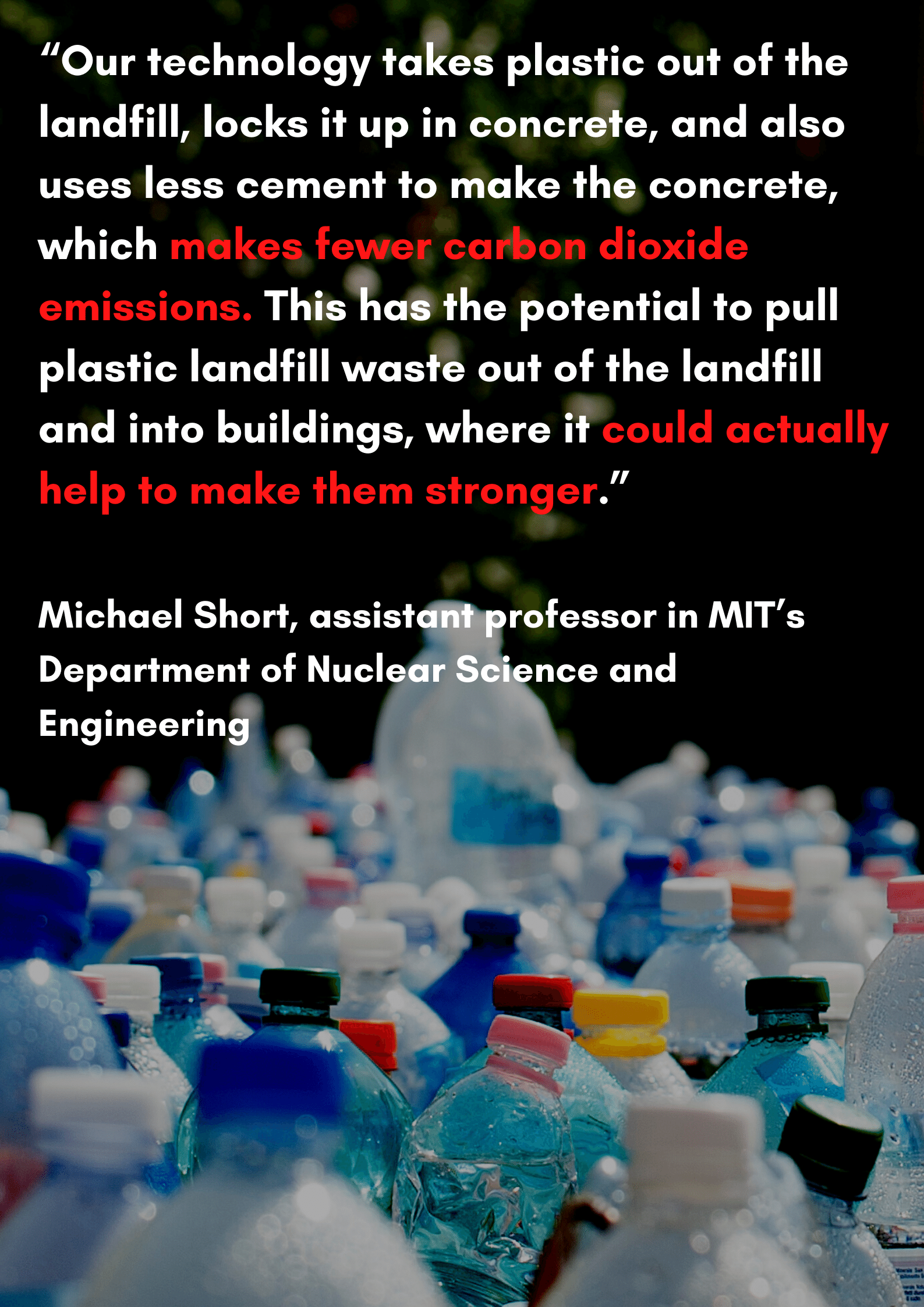

Gamma radiation + plastic = stronger concrete (MIT research)

Plastic has traditionally weakened the structure of cement: one reason it’s not widely used as an ingredient.

But researchers from Massachusetts Institute of Technology have found a solution:

Radiation – in harmless doses.

They replaced 1.5 per cent of cement aggregate with powdered plastic that’s been blasted with gamma rays, to change its structure.

The results?

Eco-friendly cement that’s up to 15 per cent stronger than non-irradiated plastic concrete samples.

Plastic has traditionally weakened the structure of cement: one reason it’s not widely used as an ingredient.

But researchers from Massachusetts Institute of Technology have found a solution:

Radiation – in harmless doses.

They replaced 1.5 per cent of cement aggregate with powdered plastic that’s been blasted with gamma rays, to change its structure.

The results?

Eco-friendly cement that’s up to 15 per cent stronger than non-irradiated plastic concrete samples.

We’ve written about this before, you might recall. It’s worth mentioning again, since their study has now been published in the Waste Management journal (Jan 2018).

An interesting read, if you’d like to find out more about the evolving journey of sustainable concrete!

We’ve written about this before, you might recall. It’s worth mentioning again, since their study has now been published in the Waste Management journal (Jan 2018).

An interesting read, if you’d like to find out more about the evolving journey of sustainable concrete!

Take the Sutherland Shire road trial, for example. The plastic was completely melted into the bitumen, which might stop microbeads from escaping.

Even so, a report by Sutherland Shire states that risks associated with the trial cannot be dismissed completely. Laying roads with plastic asphalt is a recent development, so field testing has been limited.

This topic is of particular interest in India, where plastic roads are becoming widespread.

Dr. Prabhakar Sharma is from the School of Ecology and Environment Studies at Nalanda University. He says rigorous testing is needed to make sure that plastic building materials don’t harm the environment.

Take the Sutherland Shire road trial, for example. The plastic was completely melted into the bitumen, which might stop microbeads from escaping.

Even so, a report by Sutherland Shire states that risks associated with the trial cannot be dismissed completely. Laying roads with plastic asphalt is a recent development, so field testing has been limited.

This topic is of particular interest in India, where plastic roads are becoming widespread.

Dr. Prabhakar Sharma is from the School of Ecology and Environment Studies at Nalanda University. He says rigorous testing is needed to make sure that plastic building materials don’t harm the environment.

“There must be field-scale testing of plastic under different soil and climatic conditions (temperature and rainfall pattern), with particular attention to the release of micro-and nanoparticles from plastics and their long-term accumulation in soils and their effects on soil quality near the road and agricultural land. In addition, it is also important to explore their impact on air quality.” Hindustan TimesDoes this mean we shouldn’t be building structures using recycled plastic? No, but there must be ongoing research and testing, to make sure we unlock the benefits in safe and healthy ways. After all, the last thing we want is to cause more harm than good, even with the best intentions.

© Copyright 2022 TPM Builders. All rights reserved.